Servomotor Repair

Here at Radwell, we have highly sophisticated Motor Repair Shops at each of our locations. Every shop is stocked with state of the art test assets and equipment. Radwell gives you the best diagnostic and repair possible.

Repair Options

Our repair solutions here at Radwell International are beyond comparison. You can rely on the expertise of our teams of engineers around the globe who provide solutions for your servomotor repair needs

All servos are fully load tested during our FREE evaluation stage, prior to your repair taking place, before we begin to repair your motor back to the manufacturer’s standard. We have thousands of test rig systems covering the most popular brands including Fanuc, Indramat (Bosch Rexroth), Mitsubishi, Allen-Bradwel, Mitchell Electronics, and Siemens, plus thousands of other manufacturers. Our wealth of knowledge in the automation industry and our extensive repair facilities around the world allows us to give you the best diagnostics and repair solutions possible.

Minor repair

- Bearing replacement

- Winding check and brake

- Check replace gaskets and seals

- Clean and re-paint to OEM color

- 100% functional test

Major Repair

- Bearing replacement

- Winding check and brake

- Check replace gaskets and seals

- Feedback replacement as needed

- Rewind (as needed)

- Clean and re-paint to OEM color

- 100% functional test

Servomotor Major Repairs

Our engineers quote for a major repair when we have found a fault during the inspection stage. The fault could be in one of the major parts of the servomotor which could include bad windings, warn brakes, bad feedback, or contamination in the motor. As part of the major repair our preventative maintenance solution, also forms part of this service.

Radwell’s Quality Servomotor Repairs

Radwell International, provides the most extensive range of quality servomotor repair solutions and servomotor test capabilities for the automation industry, from AC, DC, Induction and Spindle servomotors to name a few. Each of our servo repair facilities are stocked with state-of-the-art test rigs and equipment, allowing Radwell to give you the best diagnostics and repairs possible. Load testing forms part of our evaluation service and we test your servomotor on our Mitchell TI5000 test system as well as on its compatible drive.

With Radwell’s extensive expertise from our servo engineers and quality assured servomotor specialists you can be certain that your motors are in good hands. Our primary focus is to provide you with the best repair solutions possible and would always advise you whether the repair or replacement makes more sense for our customer

The repair process

Inspection and Evaluation

Inspect, fully test and diagnose the fault, create a unique factory datasheet, log mechanical and electrical information of your servomotor onto our systems. Disassemble motor for further inspection to find all faults, availability of parts and pricing, before sending you a repair quote. Once the price and turnaround time is agreed upon, we can repair your servomotor.

Test, Clean and Report

Fully test servomotor on the diagnostics rig, test the feedback, windings, brakes if applicable, and all mechanical parts. Power test the motor and run it on its compatible drive, clean and lubricate the front bearing if reachable. At this stage, your test report will be printed and sent to you.

Radwell’s Preventative Maintenance Solution

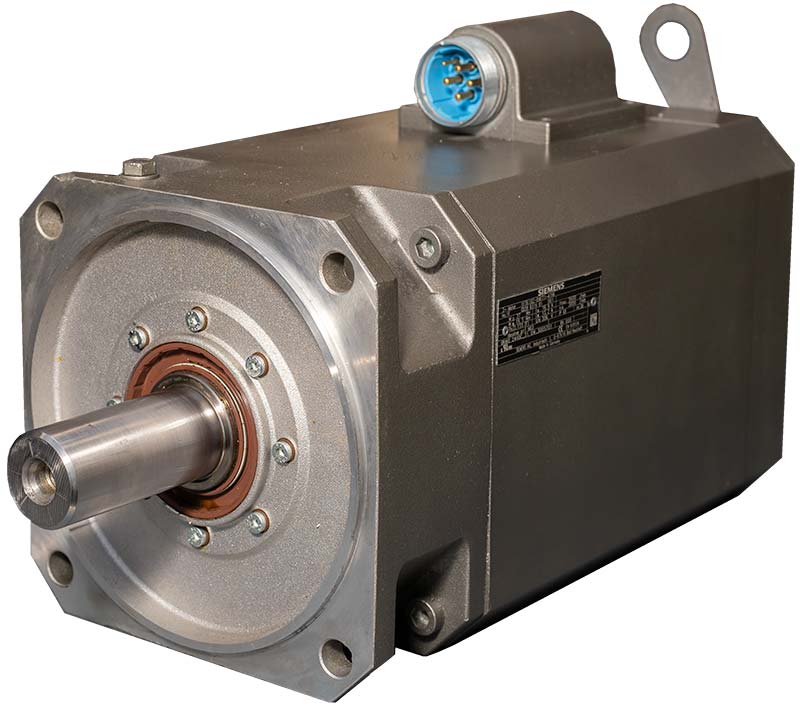

Offers a full service on your servomotor unit, including inspection and evaluation. Your servomotor parts are overhauled, cleaned, and tested which includes replacing seals, bearings, and gaskets. All parts are lubricated, reassembled, realigned, and tested with our diagnostics and generic run test systems. Your servomotor is sandblasted and resprayed then returned to you looking as good as new!

Our Servo Motor Overhaul Service

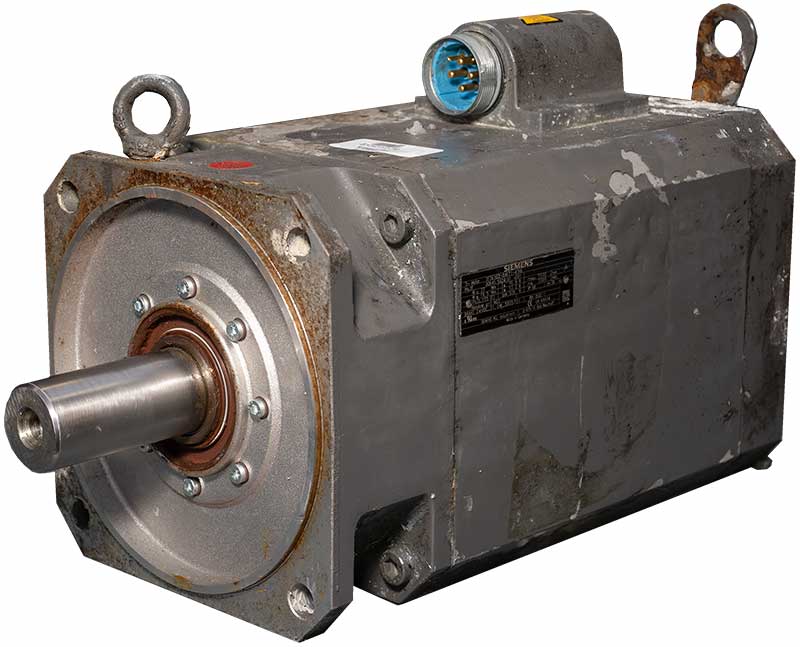

As part of your servo motor repair service we sand blast and respray your motor before returning it back to you, looking like new! Take a look at the before and after pictures for the SIEMENS servo motor below as an example of our work.

All servos are fully load tested during our FREE evaluation stage, prior to your repair taking place, before we begin to repair your motor back to the manufacturer’s standard. We have thousands of test rig systems covering the most popular brands including Fanuc, Indramat (Bosch Rexroth), Mitsubishi, Allen-Bradwel, Mitchell Electronics, and Siemens, plus thousands of other manufacturers. Our wealth of knowledge in the automation industry and our extensive repair facilities around the world allows us to give you the best diagnostics and repair solutions possible.

Our repairs are guaranteed

All our servomotor repair solutions come with our 2-year warranty or a 3-year extended warranty for an additional premium cover. Let Radwell’s 150 engineers around the globe and our multi-award-winning industrial automation expertise provide you with the solutions our customers receive every day. With our friendly customer-focused engineers and teams you can be sure you will be supported with quality servomotor repair solutions every step of the way.